Soğuksan Automatic Fryer is designed to meet the frying needs of large scale companies, hospitals, universities and military units in the kitchen and to achieve fast, efficient, hygienic, economical production.

System

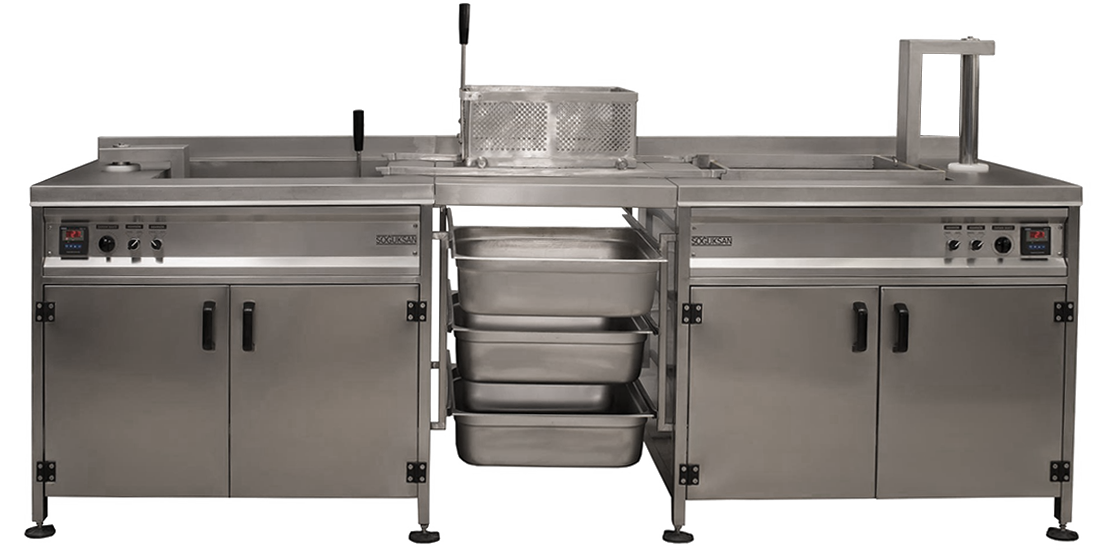

The automatic frying machine consists of two frying and one medium product unloading counter. The raw product in the frying basket is brought to the cooking chamber with the help of the rails. The cooking time is set, the machine moves to automatic position, the changing basket goes down, and the frying process starts. The same process is done in the other cooking basket. At this time, the first product is cooked and is lifted up with the help of the lift. The basket is drawn to the unloading table, the product is unloaded by pulling the damper lever. New product is placed in the cooking chamber. This process continues quickly until the products to be fried are finished.

Frying Basket

Capacity of the frying baskets are 8 + 8 kg product. It just moves on the rails. The basket comes out of its own frying hopper, and is pulled into the discharge hopper by means of the rail. The damper under the basket opens by pulling the discharge arm . The product is discharged into a GN2 / 1 gastronorm pan.

Long Oil Life

Because the specially designed hidden tube heaters are not in direct contact with the oil, it is very unlikely for the oil to be burnt out or deformed. There are four each tube heaters inside the frying hoppers. The frying operation is controlled by temperature control devices.

Technical Specifications |

Frying Capacity |

||

| Total Oil Capacity | : 85 + 85 lt | Each Load | : 8 + 8 kg |

| Power | : 24 + 24 kW | ||

| Power Supply | : 220-380 V AC-50 Hz |

|

|